Some customers will encounter the following problems during use:

1. The wire diameter fluctuates greatly during wire drawing

2. The drawing die has to crack even after not using so for a long time

3. The service life of the drawing die is too short

4. The surface of the wire after the drawing is cracked and rough

Next, let me tell you the reasons,

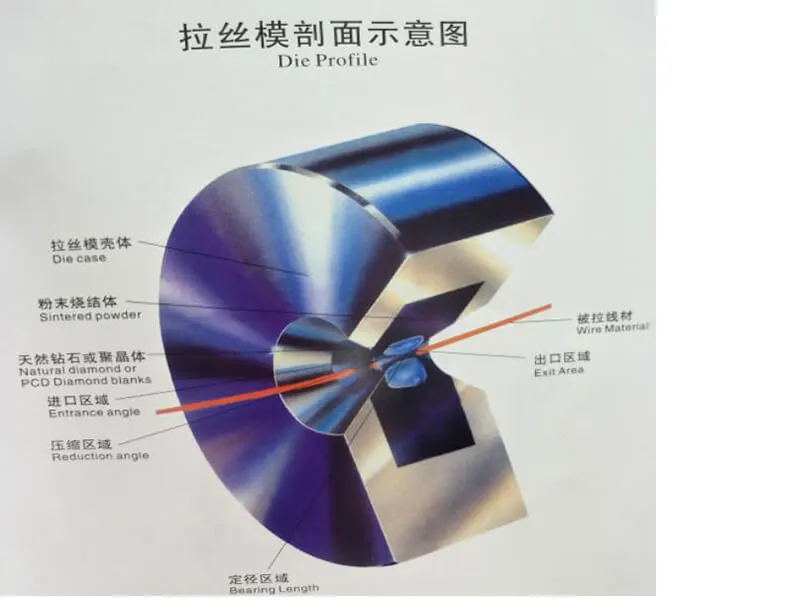

The first influencing factor is the Reduction Angle.

The Reduction Angle is the area of wire drawing deformation, and the angle of compression zone (Reduction Angle) is the main parameter of the compression zone of the wire drawing die. The size of the reduction angle plays a decisive role in the size and distribution of the pressure acting on the inner hole of the drawing die, the size of the drawing stress and the mechanical properties of the drawn wire rod.

If the angle of the Reduction area is too large, the deformation rate will increase, and the deformation zone will become smaller when the metal material is in the control process, which will make the drawing die to produce a lot of heat, scorch the lubricating powder and make it invalid, thus seriously affecting the wire drawing effect.

What happens if the reduction area angle is too small? When the angle of the reduction zone becomes smaller, the drawing die will produce a lot of heat, which will lead to the failure of lubricating powder.

The second influencing factor is: Bearing Length.

The bearing length is the control part of the die aperture size, through which the metal wire can get the final size.

The bearing length must be straight and reasonable in length. If the bearing length is too long, the pulling wire friction force will increase. When the wire rod is pulled out of the die hole, it is easy to cause diameter reduction or wire breakage. If the bearing length is too short, it is difficult to obtain a wire rod with a stable shape, accurate size and good surface quality, and the die hole will wear out of tolerance quickly.

To sum up, as a wire manufacturer, in order to obtain stable long-time drawing, accurate size, good surface quality, reduce cost and create large economic benefits, it is necessary to detect the groove structure of wire drawing die: the suitable reduction angle and bearing length.