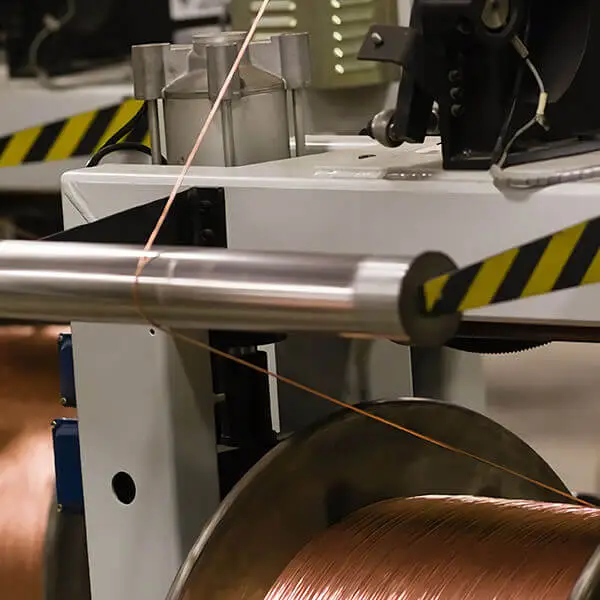

Indian customers pull stainless steel wire for cleaning ball wire

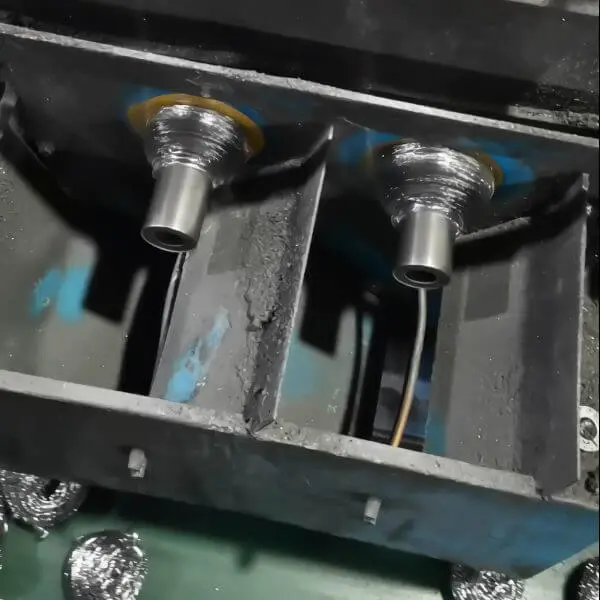

PCD diamond wire drawing die is made of micron diamond particles and binder sintered under high temperature and high pressure. It has the advantages of high hardness, good wear resistance and strong impact resistance. During the use of the die, it shows uniform wear and long life. Advantages, suitable for high-speed drawing.

Case show: Indian customers pull stainless steel wire for cleaning ball wire

Since PCD is macroscopically isotropic, it does not suffer from uneven wear of the die hole and out-of-roundness of the die hole like a single crystal diamond. In addition, because the price of PCD is much lower than that of single-crystal diamonds, it has been widely used in the wire drawing industry. At present, most of the diamond wire drawing dies use PCD wire drawing cores. According to the different bonding agents, PCD cores can be divided into two types: cobalt-based and silicon-based. Cobalt-based PCD cores contain metal binders and have good machinability. They can be processed by EDM, laser, ultrasonic and other processes, but the presence of metal cobalt makes diamonds prone to graphitization at high temperatures, so this type of core is Suitable for processing and use below 650 degrees Celsius. Silicon-based PCD cores are relatively poor in processability, but there is no metal bond in the material, so the material can still maintain good thermal stability at 1000 degrees Celsius.