Radial Tire Industry Solution

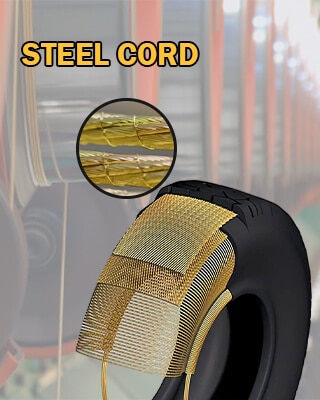

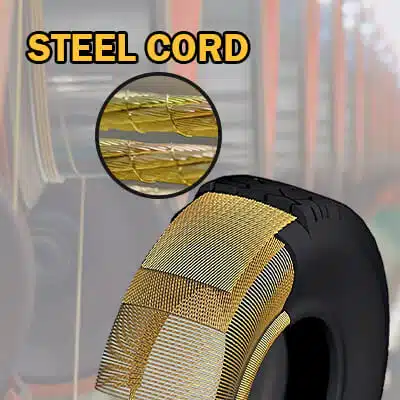

In the radial tire industry, wire drawing dies are critical for producing precise, smooth steel cords that ensure tire strength, flexibility, and superior rubber bonding performance.

Radial Tire Industry (Steel cord for tire reinforcement)

- Ensures ultra-fine and uniform steel cords (typically 0.15–0.38 mm), enhancing the tire’s load-bearing and pressure resistance.

- Produces smooth surfaces ideal for subsequent coating processes (e.g., brass plating), improving bonding with rubber.

- High-quality dies (such as PCD dies) enable high-speed drawing with excellent dimensional stability and reduced wire breakage.

- Suitable for step-by-step diameter reduction from thick steel wire to final steel cord specifications.

Recommended Wire Drawing Dies Products

Choosing the appropriate wire drawing die material is crucial for improving production efficiency, extending die life, and ensuring wire quality when drawing copper and aluminum wires.

| Feature | Nano Wire Drawing Die | Pressure Wire Drawing Die | PCD Wire Drawing Die |

|---|---|---|---|

| Structure & Material | Tungsten carbide (WC-Co) base with CVD-deposited nano-scale diamond composite coating | Tungsten carbide with specially designed pressure geometry | Polycrystalline diamond (PCD) formed by sintering diamond particles under high temperature and pressure |

| Wear Resistance | High – 5 to 10 times longer lifespan than standard carbide dies | Moderate – suitable for mid-strength wire drawing | Very high – ideal for long production cycles |

| Surface Finish | Excellent – ultra-smooth with low friction, minimizes damage to wire structure | Good – reduces surface scratches and internal stress | Good – maintains consistent surface quality over time |

| Dimensional Accuracy & Stability | Excellent – stable bore size reduces downtime and die replacement | Moderate – suitable for general tolerance requirements | Excellent – reliable for consistent long-run diameter control |

| Application Scope | Ideal for ultra-fine steel wire (e.g., <0.15 mm), especially for premium radial tire manufacturing | Used in intermediate drawing passes to improve material flow | Standard die for mass production of steel cords |

| Cost & Maintenance | Higher upfront cost, but lower long-term cost due to longevity; not suitable for repolishing | Moderate cost; easy to refurbish and maintain | Higher cost, but offset by durability; can be polished multiple times |

| Typical Use Case | Precision drawing of high-end steel cords for premium radial tires | Mid-stage drawing to optimize material deformation and flow | General-purpose drawing for large-scale steel cord production |

Nano Wire Drawing Die: Utilizes CVD technology to deposit nano-diamond coatings on carbide dies, offering superior wear resistance and surface finish. Best suited for high-precision drawing of ultra-fine steel cords in premium radial tire production.

Pressure Wire Drawing Die: Designed with pressure geometry to enhance material flow and reduce drawing stress. Ideal for intermediate steps in multi-pass wire drawing, especially when processing high-strength steel wires.

PCD Wire Drawing Die: Made from polycrystalline diamond, known for its exceptional hardness and dimensional stability. Widely used in mass production of steel cords for radial tires.

Latest Offers

Get the latest pricing information and contact us today.