Prestressed Concrete Wire Solution

Wire drawing dies are essential for precisely reducing the diameter of high-carbon steel rods to produce high-strength, low-relaxation steel wires used in pre-stressed concrete structures, ensuring structural integrity, high tensile strength, and minimal elongation.

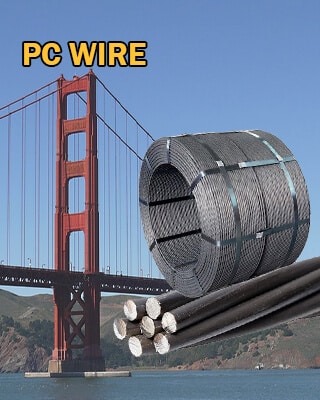

Pre-stressed Concrete Wire (PC Wire)

- Pre-stressed concrete wires must have strict diameter tolerance (e.g., 4.0 mm–7.0 mm ±0.01 mm) and smooth surfaces to ensure uniform stress distribution when tensioned.

- The drawing process refines the steel’s grain structure, increasing tensile strength (commonly over 1700 MPa) and reducing residual stresses, which is critical for the performance of PC structures.

- High-quality drawn wires are better suited for subsequent processes like stress relieving (low relaxation) and surface coating (e.g., epoxy, galvanized).

Comparison of Wire Drawing Dies for the Pre-stressed Concrete Wire Industry

When drawing high, medium, and low carbon steel wires, choosing the right wire drawing die material is crucial to improving production efficiency, extending die life, and ensuring wire quality.

| Feature / Type | Nano Wire Drawing Die | PCD Wire Drawing Die | Tungsten Carbide Wire Drawing Die |

|---|---|---|---|

| Material Structure | Tungsten carbide base with nano-scale CVD diamond coating | Synthetic polycrystalline diamond | Tungsten carbide with cobalt binder |

| Wear Resistance | Very high – significantly extends die life | Extremely high – suitable for heavy continuous production | Moderate – wears faster, especially in heavy-load drawing |

| Surface Finish Quality | Excellent – produces smooth, defect-free wire surfaces | Very good – maintains consistent finish over long runs | Good – acceptable, but higher risk of minor surface flaws |

| Dimensional Stability | Excellent – critical for maintaining tight tolerances | Excellent – very low dimensional drift | Moderate – frequent adjustments may be required |

| Effect on Wire Tensile Properties | Outstanding – promotes high tensile strength and uniformity | Very good – maintains mechanical property consistency | Moderate – possible variation due to higher friction |

| Suitable Wire Size Range | Medium to large wires (typically 4–7 mm for PC Wire) | Medium to large wires | Broad range, but less stable for very tight tolerance needs |

| Cost | High upfront, better long-term ROI due to fewer changes | High upfront, economical for mass production | Low to medium initial cost |

| Maintenance / Re-polishing | Limited – replacement needed after coating wears | Difficult to polish but durable for extended runs | Easy to refurbish and polish multiple times |

| Typical Use Cases | Premium PC wires for critical infrastructure projects (bridges, highways, large buildings) | High-volume PC wire manufacturing | General PC wire production with moderate quality requirements |

Nano Wire Drawing Die: Best suited for premium-grade pre-stressed concrete wires where ultimate surface quality, tight tolerance, and maximum tensile strength are required — ideal for critical infrastructure applications.

PCD Wire Drawing Die: Best for large-scale production of PC wires, offering excellent balance between cost, wear resistance, and product consistency.

Tungsten Carbide Wire Drawing Die: The most economical choice, acceptable for general PC wire applications where extremely high precision is not critical.

Recommended Wire Drawing Dies Products

Latest Offers

Get the latest pricing information and contact us today.