Steel Wire Rope Drawing Solution

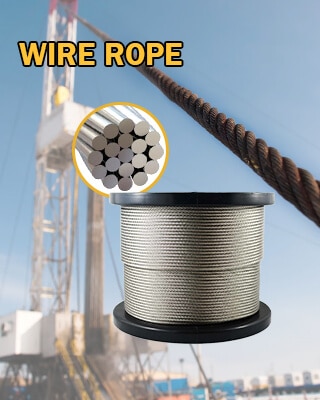

Steel wire ropes are widely used in heavy-duty applications such as cranes, elevators, mining, and offshore platforms. Due to their high tensile strength and abrasive nature, drawing these wires requires superior dies that can withstand extreme wear and pressure. Our wire drawing dies offer the ideal solution for this demanding application.

Why is a drawing die required for steel wire ropes?

- The drawing wire dies ensures that each wire reaches the specified fineness (e.g. 1.0mm, 2.0mm, etc.), facilitating subsequent multi-strand stranding into wire ropes and ensuring overall uniformity and load capacity.

- Raw coarse steel bars are usually subjected to multiple stages of wire drawing dies to reduce the size of the wire to obtain a wire suitable for rope braiding.

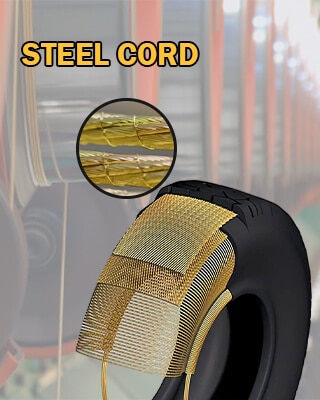

- The wire drawing dies can be used to draw wire of different materials (e.g. high carbon steel, stainless steel, galvanized steel) to meet the requirements of different application scenarios.

Application Fields & Dies Recommendations

Steel wire rope is a type of metal rope with high strength, good wear resistance, and strong flexibility, widely used in multiple industries.

As a professional die manufacturer, we provide tailored tooling solutions for various steel wire rope applications. Our dies help improve drawing performance, extend tool life, and ensure high-quality output.

| Application | Wire Drawing Die Material | Stranding Dies Material | Key Features |

|---|---|---|---|

| Lifting Equipment | PCD / Tungsten Carbide/Nano | Tungsten Carbide (TC)/Nano | High wear resistance, strong and compact |

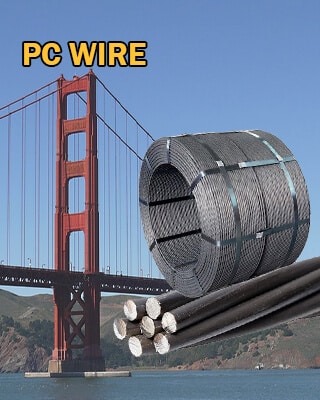

| Bridge & Tensioning | Tungsten Carbide / PCD/Nano | PCD / Nano | Precision tolerance, concentricity |

| Power Transmission | PCD / ND (Natural Diamond) | PCD | Smooth surface, excellent conductivity |

| Elevator Systems | PCD / Nano Coated | PCD / TC/Nano | Quiet, stable running, long life |

| Cable Cars | ND / Nano Coated | ND / PCD | Ultra-high precision & durability |

| Forestry & Agriculture | Tungsten Carbide (TC)/Nano | TC/Nano | Impact resistance, cost-effective |

Comparison of Wire Drawing Dies for Steel Wire Rope Industry

| Feature / Type | Nano Wire Drawing Die | PCD Wire Drawing Die | Tungsten Carbide Wire Drawing Die |

|---|---|---|---|

| Material Structure | Carbide core + nano-scale CVD diamond-like carbon coating | Synthetic diamond particles sintered under high pressure | Tungsten carbide with cobalt binder |

| Wear Resistance | Very high (5–10× that of carbide dies) | Extremely high (best for mass production) | Moderate (lower than Nano and PCD) |

| Surface Finish Quality | Excellent – ultra-smooth surface, minimizes wire damage | Very good – consistent surface quality | Good – but prone to more friction and scratches |

| Dimensional Stability | Excellent – maintains tight tolerance over long runs | Excellent – very stable over large volumes | Moderate – more frequent size adjustments needed |

| Wire Fatigue Resistance Enhancement | Outstanding – best surface to reduce micro-cracks | Very good | Moderate |

| Suitable Wire Size Range | Fine to medium wires (0.5–2.5 mm) | Fine to medium wires (0.5–2.5 mm) | Broader range but less stable for ultra-fine wires |

| Cost | High upfront, low long-term due to longevity | High upfront, low long-term | Low to medium |

| Maintenance / Re-polishing | Limited – thin coating, replacement needed after wear | Difficult – polishing possible but limited cycles | Easy to refurbish and polish multiple times |

| Typical Use Cases | Premium steel wire ropes (aviation, elevators, offshore) | Mass production of general-purpose wire ropes | Cost-sensitive, general-purpose wire ropes |

Nano Wire Drawing Die: Best for ultra-smooth surface finish, improving fatigue life, perfect for premium-grade steel wire ropes requiring maximum safety and performance.

PCD Wire Drawing Die: Best for extremely large-volume production, offering long lifespan and consistent dimensional control.

Tungsten Carbide Wire Drawing Die: Most economical, suitable for general steel wire rope production, but with lower durability and finish compared to Nano and PCD dies.

Recommended Wire Drawing Dies Products

Request a Custom Solution

Looking for optimized die configurations for your steel wire rope line?